In the glass industry, Tempered Glass (tempered glass) has become a favored material due to its unique properties and wide range of applications. Tempered glass, also known as tempered glass or strengthened glass, is prestressed glass that has undergone a special heat treatment to provide significantly increased strength and impact resistance.

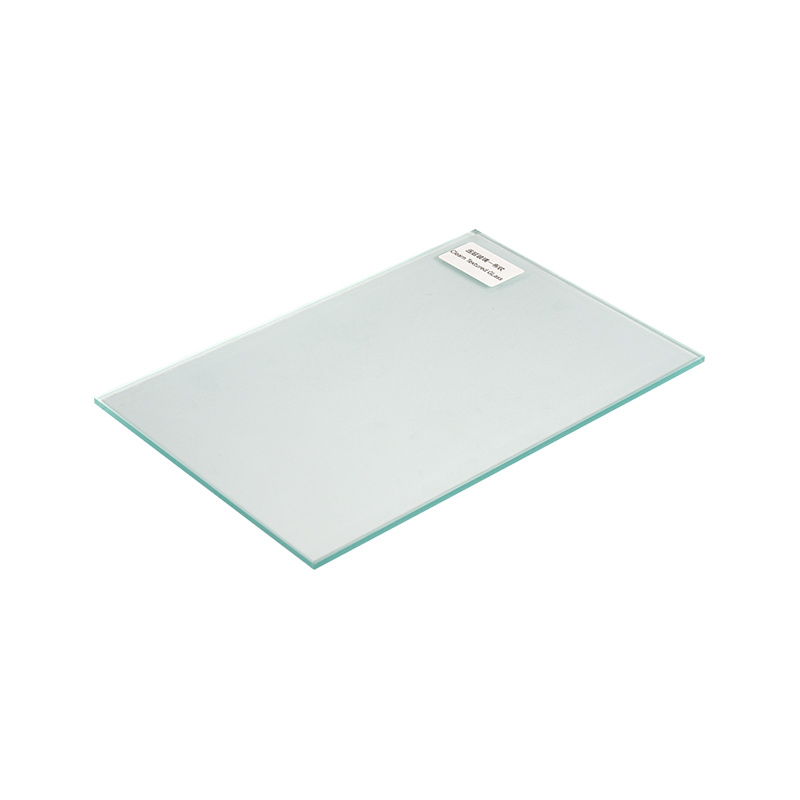

What makes tempered glass stand out among other glass types is its unique physical and chemical properties. The safety of tempered glass is one of its most notable features. When damaged by external force, tempered glass will not form sharp fragments like ordinary glass, but will break into small honeycomb-like obtuse-angled particles, greatly reducing the risk of harm to the human body. This characteristic makes tempered glass the preferred material for many applications that require high safety standards, such as automobile windows, building curtain walls, etc.

Tempered glass has high strength. Compressive stress is formed on the glass surface through chemical or physical methods. The impact strength and bending strength of tempered glass are 3 to 5 times that of ordinary glass. This means that with the same thickness, tempered glass can withstand greater external forces without breaking, thus improving its service life and safety.

Tempered glass also has good thermal stability. It can withstand higher temperature changes than ordinary glass, usually up to 300°C, which allows tempered glass to maintain stable performance under extreme climate conditions.

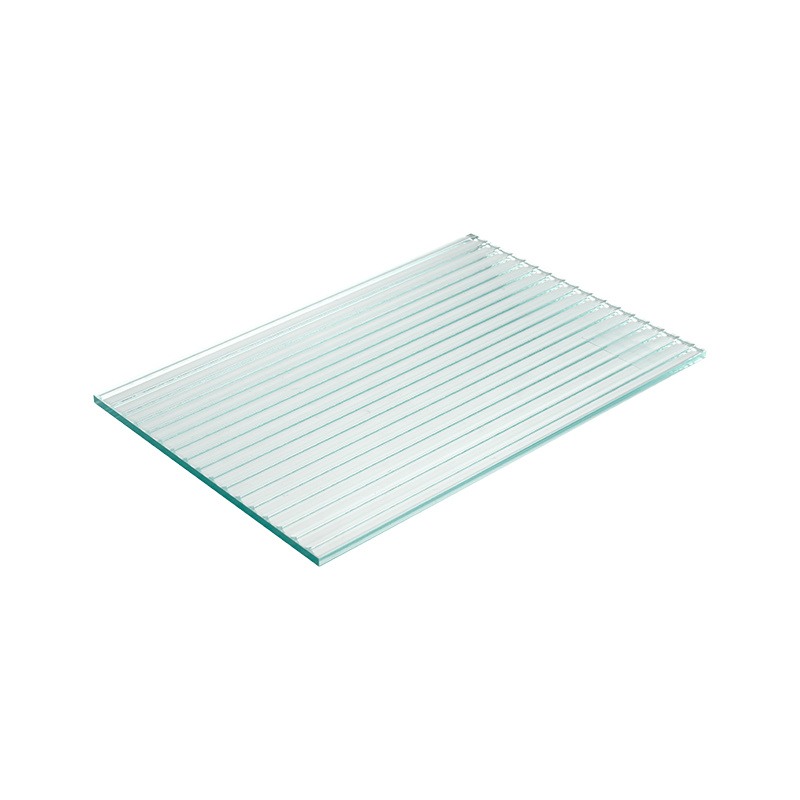

The manufacturing process of tempered glass mainly includes steps such as glass cutting, glass grinding, heating and rapid cooling. First, ordinary float glass or flat glass is cut to the required size and finely ground to ensure a flat and smooth edge. The glass is then placed in a tempering furnace for heating, usually at a temperature between 650°C and 700°C. During the heating process, the atomic structure inside the glass changes, forming a certain prestress. Then, the heated glass is rapidly cooled, usually using air cooling or water cooling, to form a compressive stress layer on the surface of the glass, thereby improving its strength and impact resistance.

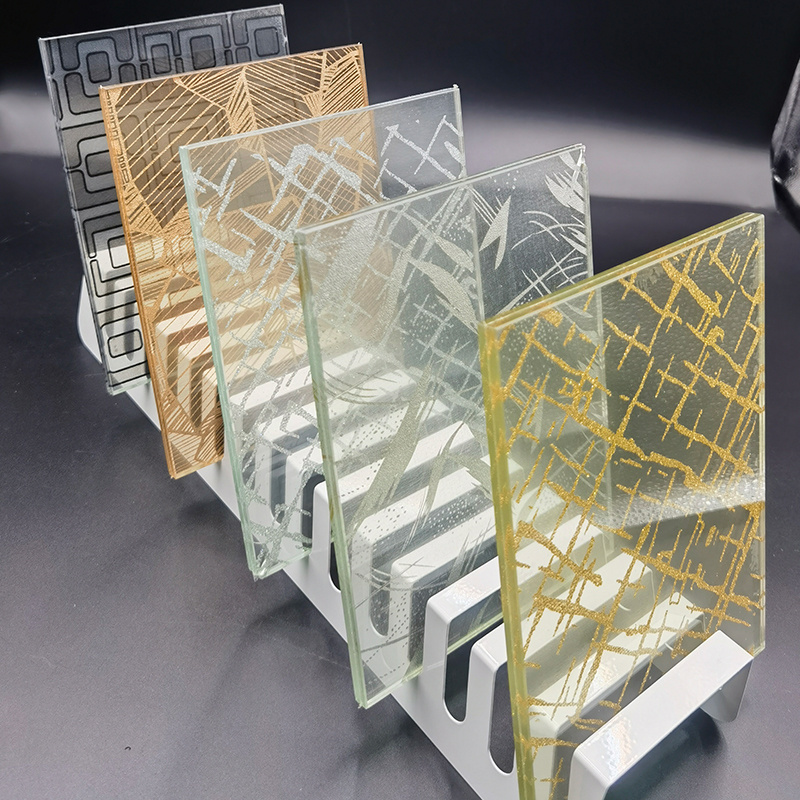

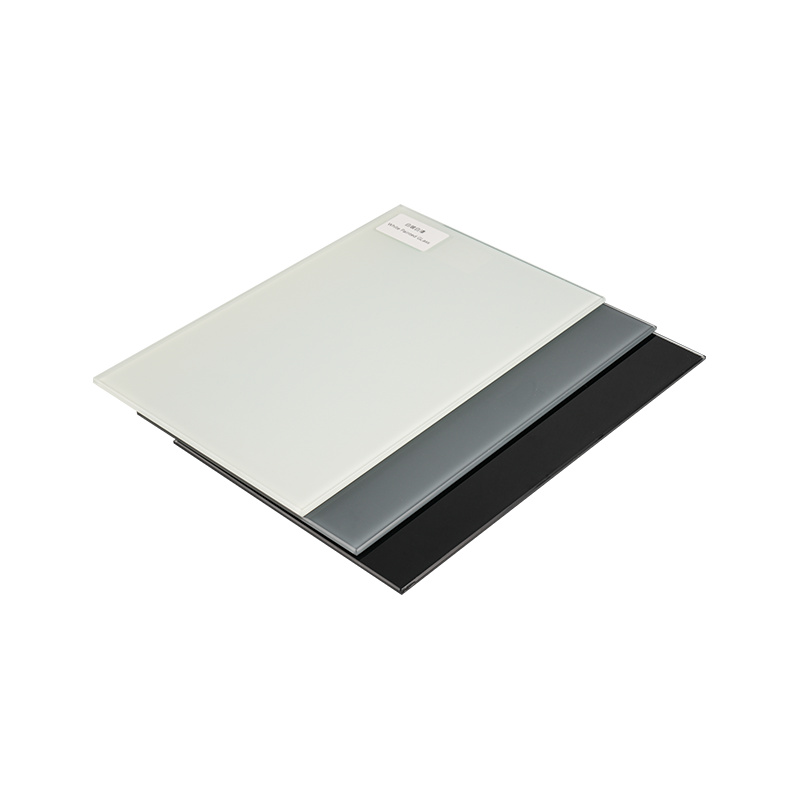

Tempered glass is widely used in various fields because of its unique properties. In the construction industry, tempered glass is often used to make curtain walls, doors, windows, partitions, etc., which not only improves the safety of the building, but also gives the building a more modern and beautiful appearance. In the automotive industry, tempered glass is widely used in car windows, windshields and other parts, effectively protecting the safety of drivers and passengers. In addition, tempered glass is also widely used in electronics, electrical appliances, furniture and other fields, bringing more convenience and safety to people's lives.

With the continuous advancement of science and technology and the improvement of people's living standards, the importance of tempered glass in modern life has become increasingly prominent. It not only improves the safety of people's living and working environment, but also brings people a more comfortable and beautiful life experience. For example, in homes, furniture made of tempered glass is not only strong and durable, but also has a stylish appearance and good light transmittance; in public places, partitions and barriers made of tempered glass not only play the role of separating spaces, but also improve the The cleanliness and beauty of the place.

中文简体

中文简体